THE BRIDGE

The Operator Command Center

Manage operations and maximize throughput to meet SLAs with The Bridge, a command center for warehouse supervisors

THE OPERATOR'S COMMAND CENTER

The Bridge captures and analyzes operational performance data from the WMS and 6RS devices, automates exceptions, and provides real-time performance and forecast dashboards to help you manage and allocate your order flow, optimize labor and realize continuous improvement.

ACCESS REAL-TIME PERFORMANCE METRICS AND ORDER PROGRESS

The Bridge provides detailed operational views and insights: hourly pick data, daily and monthly volume data, and daily performance.

Customizable real-time reports and dashboards empower operators to optimize productivity, SLA compliance and labor performance and utilization.

OPTIMIZE ASSET UTILIZATION

Chuck location, utilization and activity information--real-time and historical--can help to optimize throughput and enable proactive troubleshooting.

Visibility into where associates are working most often can help operators to better slot inventory and alleviate congestion.

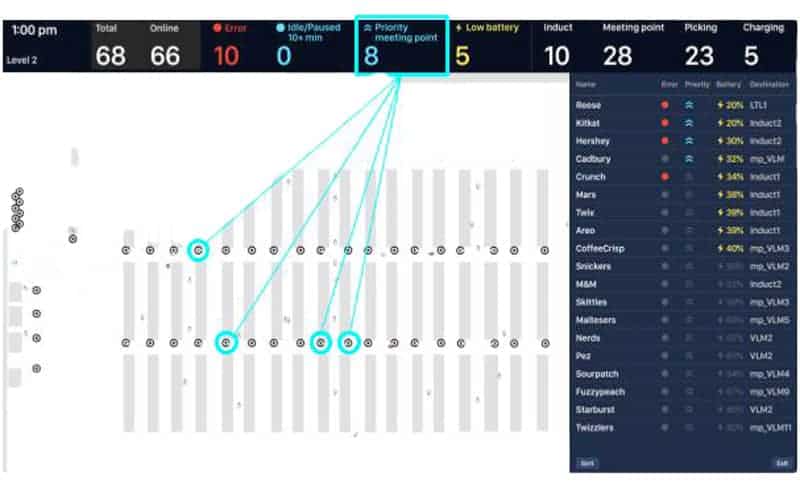

HIGH PRIORITY CHUCK

Direct your associates to the most important Chucks at the right time. The Bridge draws attention to those Chucks by categorizing them as high priority and the Chucks themselves provide multiple visual indicators. Configure rules based on cutoff times, order priority and Chuck idle time to meet ever-tighter SLA requirements.

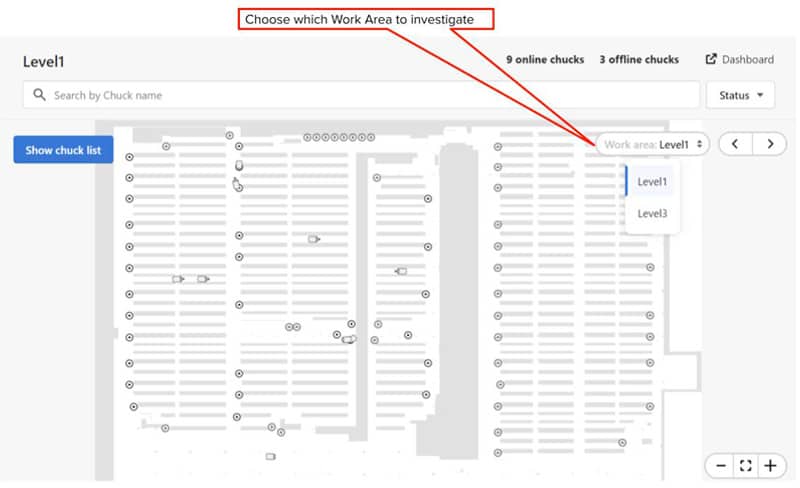

WORK AREAS

The Bridge lets you monitor and manage activity across all of your work areas, all in one place, whether they extend into mezzanines, multiple floors or different regions of your warehouse.

Simulate how your orders flow

through the 6RS solution

The Business Case for Collaborative Mobile Robotics

Based on interviews with more than 25 early adopters of collaborative mobile robots (CMR), this report assesses how CMR increase labor productivity and flexibility, yield a multi-million dollar net present value and deliver a 15-month return on investment.