Boost your warehouse productivity

Exceed customer expectations, grow profits, and reduce risk with our industry-leading warehouse automation system, combining advanced fulfillment algorithms with autonomous mobile robots (AMRs).

EXCEPTIONAL EXECUTION

Reduce your cost per unit shipped and grow more profitably

Algorithmic optimization

Achieve higher throughput by leveraging our patented, system-directed algorithms rather than relying on associates’ judgment to calculate optimal task allocation and path planning.

Performance metrics

Benchmark your sites’ performance relative to your peers to help identify opportunities to fine-tune your operations in an increasingly competitive landscape.

Systems integration

Integrate with any host WMS and a wide range of software systems, including ERP, OMS, and Labor Management Systems, reducing the burden on your critical IT resources.

Drive new levels of efficiency

Maximize your operations with unparalleled capacity, flexibility,

and insights

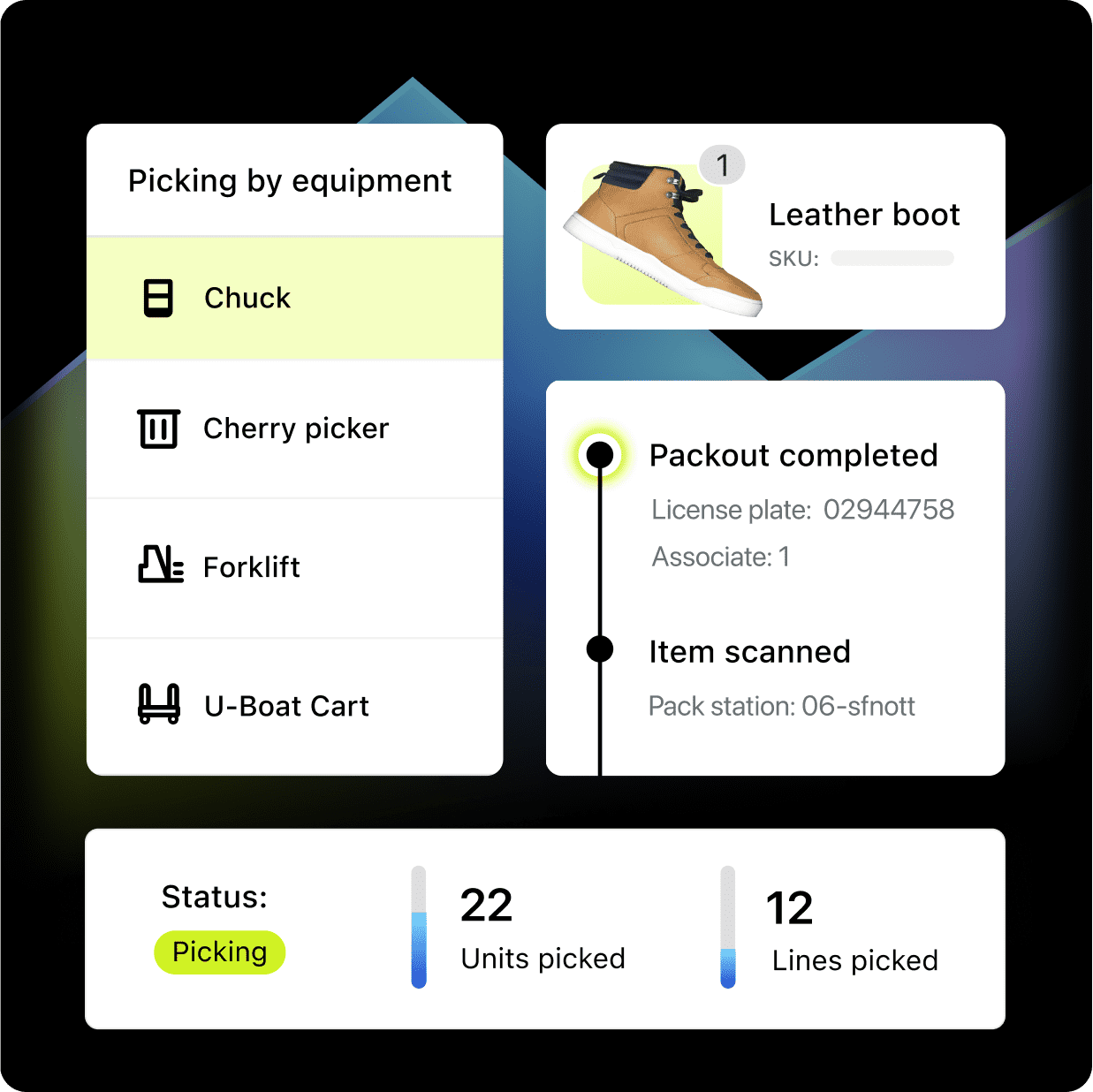

Most configurable system

Chuck, our AMR, is highly configurable to accommodate many SKU sizes and containers. Our cloud-based software platform adapts to your needs: enabling batch picking, turning on and off static and dynamic zones options as needed, and supporting alternate pick locations are just a few examples.

High capacity

Reduce cost per unit shipped with the highest throughput per bot. Chuck’s high capacity and support for a wide range of onboard accessories, paired with cloud-based algorithms, are proven to execute tasks more efficiently than other leading systems.

Scalable systems

Start with a system that meets your needs today and easily scale to meet future growth requirements. Right-size your Chuck fleet with the flexibility to rent capacity for peak needs. Easily redeploy assets or add capacity to meet demand across your network.

Real-time data insights

Resolve operational bottlenecks faster so your managers can work on higher-value tasks. The Bridge captures and displays detailed, real-time utilization, labor, and other data points across all of your sites on easy-to-read dashboards.

Elevate Human Performance

Address your labor challenges while increasing productivity

Perform consistently

Our system-directed approach allows you to better predict capacity and plan your operations.

Stabilize your labor issues

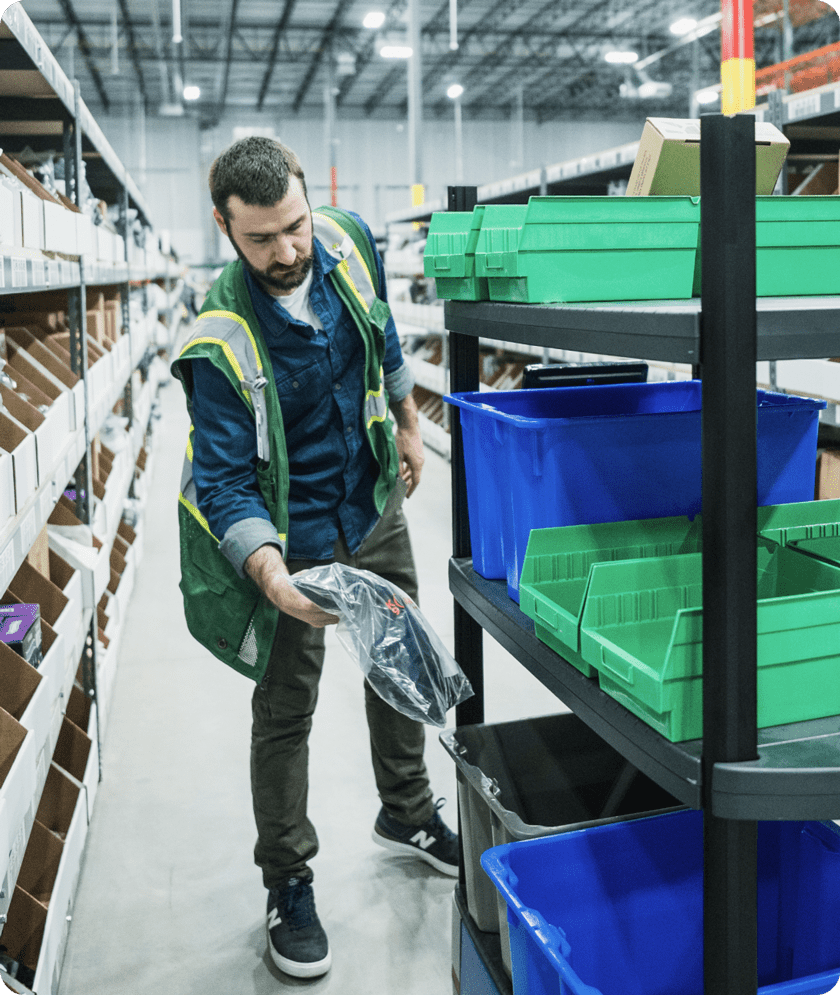

Attract and retain the best team members. Our simple and modern user interface means associates can start picking in minutes and don’t need warehouse experience to ramp to high productivity quickly.

Retain your best associates

Reduce employee fatigue from working with heavy carts. Chuck does all of the heavy lifting and navigation.

Easily cross-train

Give managers the flexibility to dynamically redeploy associates across many roles with our common user experience for all of our wall-to-wall touchpoints (putaway, pick, sort, and packout).

IMPROVE PREDICTABILITY

Reduce risk today and tomorrow

We are an industry leader with thousands of robots in the field at over 100 sites across North America and Europe.

Do more, with less, faster

Double your cart picking productivity at 20% of the cost of heavier automation and deploy in weeks, not months to years for fast time to value. Your associates will also perform more consistently at high capacity allowing you to exceed ever higher customer SLA demands.

Minimal business interruptions

Use your existing physical and network infrastructures, allowing for rapid deployment, minimal downtime, and a quick return on your investment.

3rd party partnerships

Eliminate many manual interventions between workstreams. Our established partner ecosystem enables direct integration with 3rd party tools such as automatic box builders, auto baggers, and vertical lift modules.

Our customers are getting results

3x

Experience a 3x pick rate improvement like Top Notch Distributors

<25%

Improve your associate error rates by 25% like NFI

<90%

Reduce training time by 90% and draw from a wider labor pool like MD Logistics