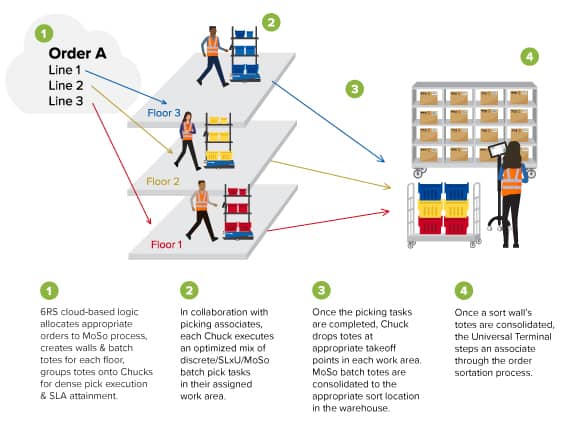

All-in-one picking and sorting solution

PICK FASTER, SORT SMARTER

As part of the 6RS wall-to-wall solution suite, Mobile Sort enables fulfillment operations to intelligently batch pick and then sort batches into discrete orders. This allows for higher pick density to alleviate congestion, or to merge picks from disparate areas of the warehouse.

INTELLIGENT AND INTUITIVE

6RS algorithms do all of the heavy lifting; building sort walls optimized for pick density and orchestrating the process from pick through sort while ensuring SLAs are met. Associates are directed by Chucks to pick batches into totes. The totes are then delivered to take-off point(s) for each wall, where they are sorted into individual orders using our intuitive Universal Terminal in conjunction with low-cost sort wall options.

The 6RS Universal Terminal can also be employed to subsequently pack out those individual orders if desired.

FLEXIBLE BY DESIGN

The 6RS sortation solution is designed with simplicity in mind. The Universal Terminal provides a modern user interface to efficiently step associates through the process of distributing batch-picked items to their respective sort wall cubbies. It can be paired with whatever physical “wall” is the best fit for your application, whether that be fixed shelving, mobile baker’s racks, or whatever makes sense for your particular application.

Depending on the layout of the warehouse and your packout workflows, your operation may need all orders of a wall fully sorted to start packout, or it may be desirable to pack out individual orders as each one independently completes the sort process. 6RS Mobile Sort supports both approaches!

The Mobile Sort workflow can be enabled and disabled with ease. Wheel in mobile sort stations during your busiest seasons, then wheel them out to reclaim precious floor space during off-peak months. Lightweight integration and mobile design allow for quick installs.

BATCH AND SORT ACROSS MULTIPLE WORK AREAS

Do you have orders that need to be picked across multiple floors, pick module mezzanines or isolated pick areas on the same floor? Mobile Sort allows you to take advantage of 6RS’ rich batching and allocation algorithms to efficiently pick those orders across all of those disparate work areas. Wave your entire order pool to our system and it will allocate orders to the appropriate workflow whether it be discrete or SLSU/SLMU/Mobile Sort batch totes.

When our algorithms cast orders into the Mobile Sort workflow, the system will optimize batch picking across work areas while also prioritizing to meet your SLAs.