SYSTEM-DIRECTED PICKING

Empower associates to be more productive

Immediate and continuous improvement in pick rates, efficiency and accuracy

DIRECTED PICKING LEADS TO IMPROVED PRODUCTIVITY

Research shows that when associates pace themselves they slow down.

Chuck directs associates through their tasks quickly, keeps them focused and drives performance consistency that enables smarter labor planning.

IMPROVE SPEED WITH DIRECTED TRAVEL

Chuck's interface can serve as a GPS for associates. A visual preview of the pick path and next destination allows your team to move more quickly, as well as spot and clear any potential obstacles that may hinder speed and productivity.

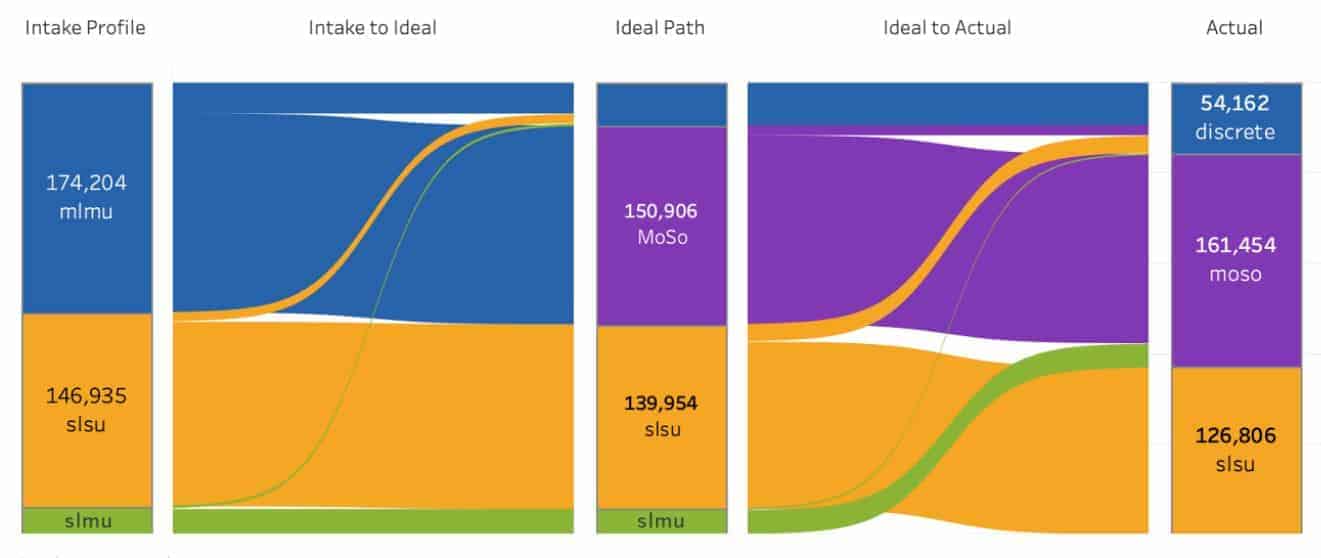

DYNAMIC ZONES: MORE PICKING, LESS WALKING

6 River Systems uses real time data to determine the optimal time for a picker to switch from one Chuck to another. This enables associates to spend more time picking products and less time walking from one place to another.

Figuring out ideal zone boundaries is no longer a problem; there are no fixed zone boundaries! The 6RS software effectively determines the perfect zone for each robot without any operator intervention.

IMPROVE ACCURACY WITH DIRECTED PICKING

Chuck's simple, intuitive UI gives associates the information they need to make fast, accurate picks. It's easy to see where the next pick is coming from, what the product looks like, how many are needed and exactly what to do.

To aid in accuracy and efficiency, Chuck and The Bridge currently support user-specific languages including English, Spanish (Mexico), Czech, Dutch and Polish. Not only can the default language be set uniquely for each user, but managers can temporarily override the language when they need to help associates complete tasks, then revert to the associate’s preferred language when done assisting.

INTELLIGENT WORK ASSIGNMENT

Directed picking starts with intelligent work assignment. 6 River Systems' (6RS) cloud-based algorithms optimize and allocate work to individual Chucks, grouping similar work to reduce associate travel.

Deploy 6RS to guide associates through discrete, zone, batch, cluster and autonomous picking as needed -- even within the same pick run for improved pick rates.