When prospects first look at our automation system, their primary focus is the productivity gains that they can expect over their current operation. Most of our customers will realize a quick ROI based on those direct benefits alone. However, there is a secondary, but very substantial benefit to our solution: faster training times.

How does 6RS Improve Training Time?

6 River Systems’ solution uses a system-directed workflow which self-trains an associate as they complete their picking, replenishment, or various other tasks in the warehouse. Our collaborative robot “Chuck” will guide associates to locations following a pre-planned path that can change dynamically, so they don’t have to know where products are stored or the fastest way to get there. Once at the location, Chuck offers simple and clear instructions on how to perform their picking work. Associates don’t need to learn complex WMS RF terminal sequences or, worse, fuss around with a piece of paper to record the activity later. Additionally, with Chuck’s built in scanner, use of product images and put-to-light system, it has a significant reduction on mispicks and other errors.

How much do we save in training a new employee?

Let’s analyze a typical new-hire scenario for a site using traditional pick carts versus a site using Chucks.

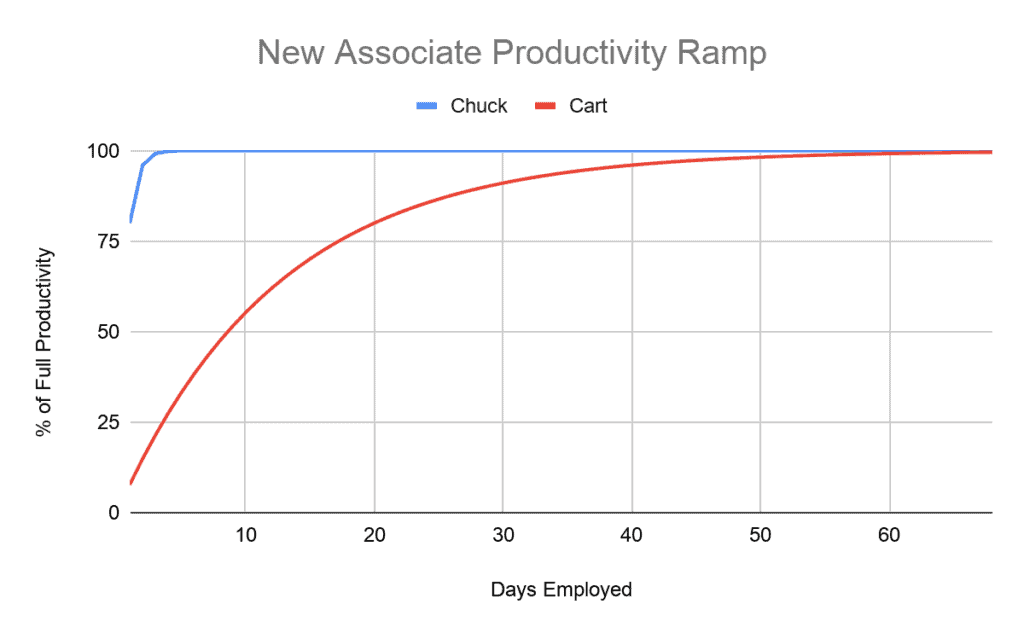

Typically, it takes 4-5 days to train an associate at a cart pick operation. However, they won’t hit expected productivity, or standard rates, for 4-6 weeks. For this comparison, we are assuming that they are 80% of standard rate in four weeks. However, the associate doesn’t magically start producing at one point; their productivity follows an increasing curve within that time period then slowly levels off as they reach full productivity rates (shown in red).

By contrast, our data shows us that Chucks help an associate up to that 80% of standard rate on day one and then to full productivity in the following few days (shown in blue). Assuming 80 Units Per Hour (UPH) for a cart pick operation, the difference between a fully trained associate and the first six weeks of a new hire would amount to about 7000 units over the six weeks shown.

In terms of labor, these 7000 units represent 87 hours or about 12 days of associate work. Assuming a cost of $13/hr, this is well over $1,100 of unproductive labor for each newly hired employee. By contrast, Chuck, performing at 160 UPH, would only have 320 fewer picks, resulting in the equivalent of 2 lost hours or $26 of unproductive labor.

Related: See why everyone at MD Logistics Loves Chuck.

Fewer interruptions for your best employees

Another benefit of Chuck is that it enables an associate to self-train. When a new associate joins the team, there is often significant time spent by floor managers or sometimes your best associates to train up the newcomer. This means that not only are the new employees not producing a high output, they are slowing down some of your most important people. Usually a senior employee spends 2-3 hours for the first 4-5 days of training, and another half hour per day for the following four weeks. This ends up being about 23 hours of the floor manager’s time and at $15/hr would be an additional ~$350 of training costs. By comparison, with less than 15 minutes of training, the associates can be up and running with Chuck, allowing these valuable employees to focus on other fulfillment tasks and exception handling.

The impact of training during seasonal peaks

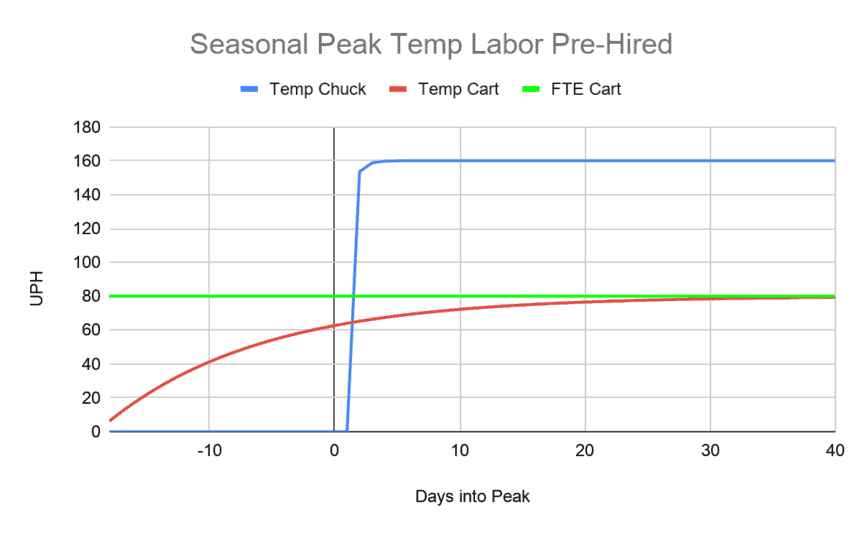

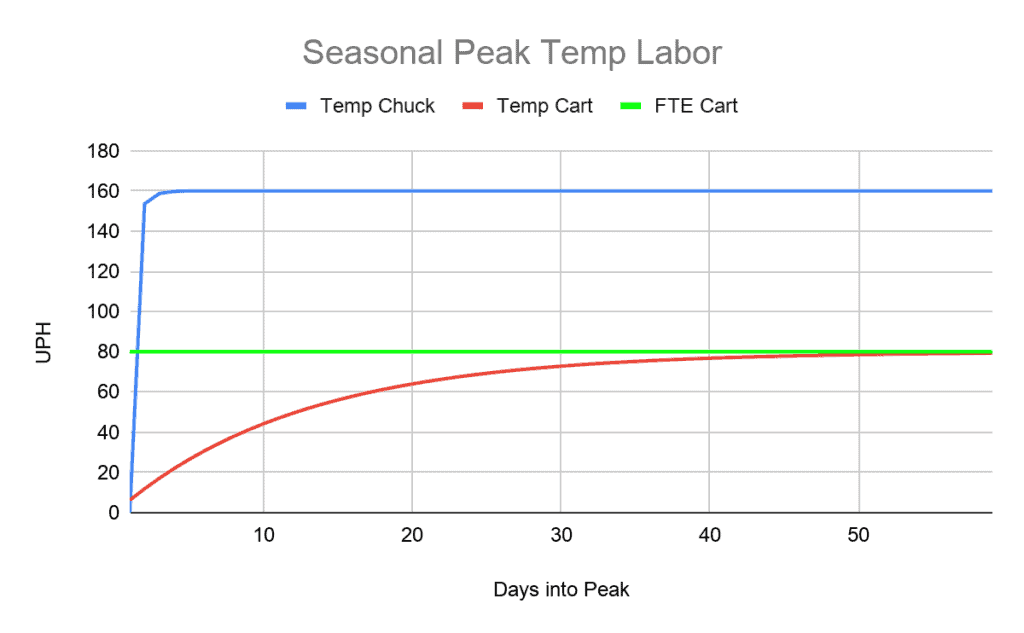

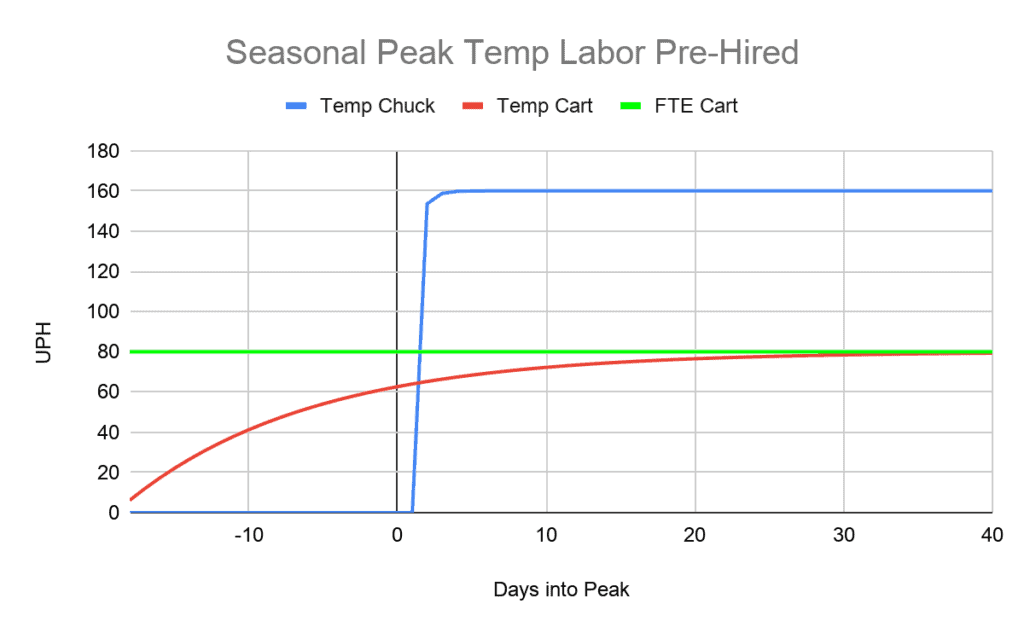

Rapid training has an even bigger impact on seasonal and other temporary labor. Let’s compare a seasonal associate with an expected productivity rate of 80 UPH (illustrated above with the green line) using a manual cart with a seasonal associate using Chuck. Assuming a typical 100% rate gain, the Chuck-enhanced associate (illustrated in blue) will reach full productivity at 160 UPH. As illustrated in the graph above, although the associate using carts to pick (the red line) is at their full UPH at the end of peak, their average rate over the entire period is only 57 UPH due to their slow ramp-up. The associate using Chuck, however, hits their stride very quickly and averages 152 UPH. In our last scenario, Chuck provided a 100% gain to your long term workforce. For seasonal workers, it provides a much greater gain: 166%!

Related: Learn how Ingram Micro prepared for a 10x increase in volume last holiday season.

The other option is to hire seasonal associates several weeks prior to peak to allow them adequate time to train. Let’s do a comparison assuming a typical 40 day peak schedule and a 20-day ramp-up time. In this scenario, you will pay labor for an extra 50% more time to train before peak. Even with this pre-training period, the average picking rate over 60 days would be 64 UPH, still giving Chucks a 138% rate advantage for these temporary workers.

Add more flexibility in your business

Possibly more important than cost savings is flexibility in your operation. The rapid training possibilities 6 River Systems provides allows for a much more agile business. For example, during the current COVID-19 crisis, many of our customers have seen unanticipated peaks as the demand on ecommerce spiked. They were able to rapidly add additional Chucks and temporary labor to adjust for this demand, far more quickly than otherwise possible. And in some cases, they picked up and moved Chucks across their different facilities to support regional spikes in volume. Temporary and portable capacity is something that no traditional automation can offer.

Final Thoughts

Increasing productivity through rate gains is one of the largest benefits of 6 River Systems’ solution. It is important to realize that there are other factors that have significant monetary and non-monetary benefits. The advantages of a system directed approach using mobile collaborative robots that assists associates in the warehouse has a huge impact on training times. This not only translates directly into the bottom line, but also allows your business to be more nimble and adjust quickly to the rapidly changing world.