National Logistics Service

Flexible automation delivers new fulfillment efficiency for a peak-prone, multi-site retail business

NLS at a glance:

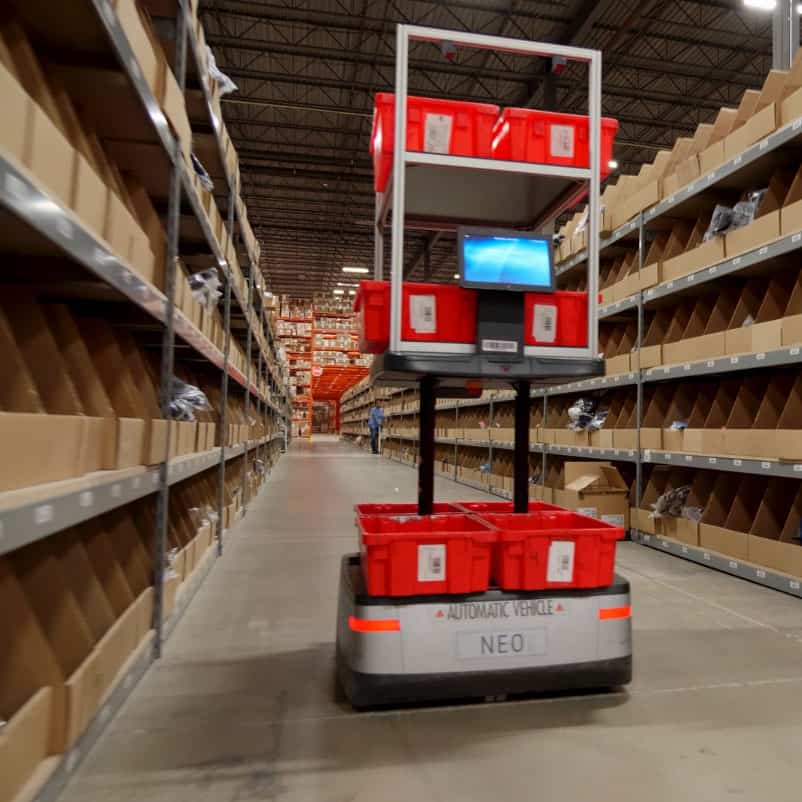

The Fleet

27 CHUCKS

+15 seasonal rentals

Industry

3PL, Retail Fashion

Benefits & Results

- 58% improvement in pick productivity

- Deployment of robots between buildings in 1.5 hours

- Training time: one pick cycle

National Logistics Services is Canada’s leading retail logistics provider. A user of 6 River Systems since 2018, NLS provides wholesale, retail and ecommerce fulfillment to top-name retail stores. A forward-thinking company, they are always looking for ways to innovate and improve the services they provide to their customers.

THE CHALLENGE

Prone to peaks in volume across their network of distribution centers, NLS often shifts labor between large sites, at times staffing upwards of 200-300 additional temporary people in a building to help meet demand from their retail customers and ever-rising direct-to-consumer activity.

The 3PL wanted to introduce a flexible automation solution to improve work for their fluctuating labor force, increase picking accuracy and efficiency, minimize training time and to adapt quickly to demand spikes, especially those from ecommerce orders.

“This solution is such a good fit for our business. The returns are significant - even without a huge capital investment.”

Gordon Brown

Director of Engineering and Innovation, NLS Logistics

THE SOLUTION

NLS has Chucks deployed in three sites, with plans to prepare multiple sites to receive any number of their robots at a moment's notice.

While they have 27 Chucks available to them year-round, NLS rents an additional 15 Chucks to support holiday volumes across their network of warehouses.

Seasonal rentals and site preparedness enables them to easily customize their robotic fleet by size and location to best support the needs of their associates at any operation.

The Results

IMPROVED EFFICIENCY

Since 2018, NLS has seen a 2x increase in business volume, year over year.

By allocating their robotic fleet between buildings to meet peaks in demand, NLS found that they could increase their throughput by 3x where and when it mattered most.

FASTER TRAINING, RELIABLE RATES

Prior to peak 2020, NLS increased their picking associates by 2.3x.

When order volume increased threefold, their newest hires were trained and ready to perform - reaching 80% of FTE performance within one shift.

GREATER FLEXIBILITY

By treating Chucks as resources to share between different warehouse sites, NLS is able to maximize the efficiency of their teams as well as their budget. No changes to infrastructure, no changes to layout, no changes to robot configuration. Just the allocation of their fleet.