Leveraging Data to Drive Optimization

Architectural hardware wholesaler increases pick rate by 3x over manual piece picking

At a glance:

Challenge:

- Too much time spent picking and walking

SOLUTION:

- 30 Chucks across 3 DCs

Results:

- 3x pick rate improvement

- Additional 16.5% pick rate improvement in 2 weeks through data insights

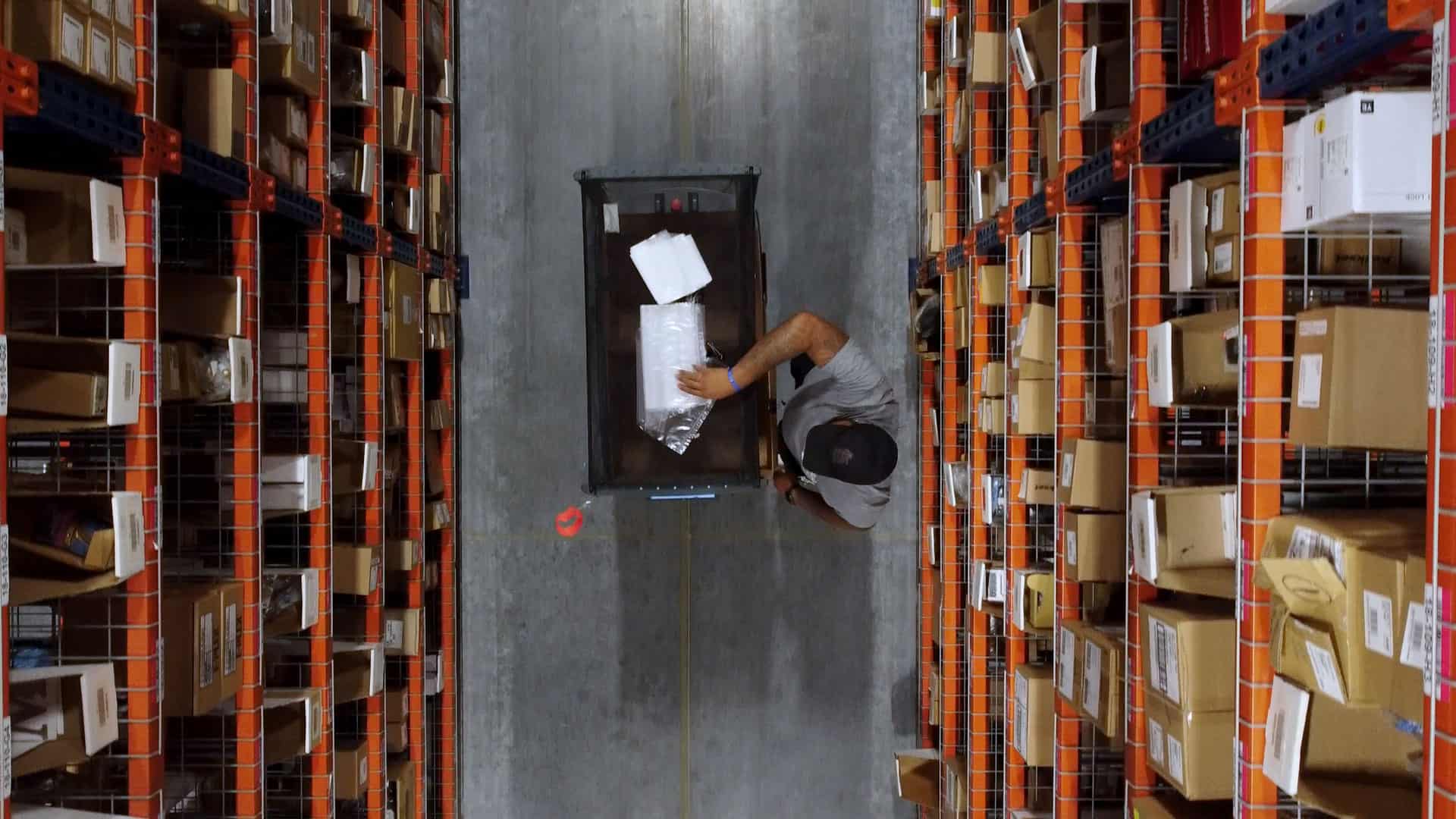

Top Notch Distributors, a premier architectural hardware wholesaler, fulfills both retail and ecommerce orders for a number of traditional hardware resellers and locksmiths in the United States.

After analyzing their operation, leaders at Top Notch found their largest labor time was spent on picking--and specifically walking--in the warehouse. Seeking to gain efficiencies in their picking operation by reducing walking time and increasing efficiency at the pick face, Top Notch engaged with 6 River Systems.

“It took us all a little while to validate and establish, but we were able to visit other customer clients and carefully look at our data to evaluate whether 6 River Systems was the right fit for us. The 6RS team visited us multiple times and through all of that, we were able to come to the conclusion that it was.”

Patrick Houlihan, Director of Operations

Establishing Confidence

For their first engagement, Top Notch deployed 6 River Systems’ solution to their recently expanded distribution center in Carson City, NV where they achieved rates 179% better than their manual pick rate. After seeing success at this first location, they moved with confidence to deploy a larger fleet of Chucks into their newly-built fulfillment center in St. Charles, MO, where they tripled their rates.

Data-Driven Decision Making

After achieving a 3x improvement in picking speed, Top Notch found that their replenishment tasks were falling behind. Catching up meant that picking would begin later in the day than before. However, despite the delayed start, they found picking rates further increased.

“As the order backlog increases, meters per line decreases and rates are improved significantly,” explains Nick Fernandez, a Robotics Performance Engineer at 6 River Systems.

In other words, orders would build up in volume within 6 River Systems’ intelligent allocation system, increasing pick density per pick run and raising pick rates. Using insights from the data their solution provides, the leaders at Top Notch refined their operational changes to drive an additional 16.5% improvement in pick rates in just two weeks.

“We were so happy with the results. We saw double what we expected out in Nevada. We knew when we came to a space like St. Charles, which was so much bigger, we were going to see an even greater value. The more orders you have, the better the technology works.”

Patrick Houlihan, Director of Operations