The future of warehousing is flexible automation. To transform supply chain operations, savvy businesses are looking to automative technology and robotics to improve productivity and maximize asset utilization. One major trend is the growing adoption of robots that work alongside human personnel — also known as collaborative robots or cobots.

Already, the global robotics market is expected to reach $13 billion by 2025. Right now, cobots make up roughly 3% of those sales, but it’s supposed to soar to 34% within the same time frame.

What is the reason for this major shift in the global robotics industry?

For one, researchers have found that human-robot teams were 85% more productive than robots or humans alone. Collaborative mobile robots, which are flexible, safe and easily programmable, are specifically designed to assist human employees as they perform various order fulfillment and warehouse activities. This easy programmability is ideal for warehousing operations, which tend to be dynamic.

Hard-programmed robots are not agile enough to handle the number of disparate tasks that crop up during order fulfillment. These types of collaborative robots, on the other hand, can be programmed on the fly to accommodate shifting priorities within the warehouse. This easy programmability significantly increases the number of tasks they can handle.

Deploying collaborative robots is a great move for companies looking to enhance productivity and drive efficiency in order fulfillment operations. However, the critical question still remains: is it the right move for you?

To help you make an informed decision, let’s take a look at some examples of how collaborative robots are transforming warehousing.

1. Easy to integrate

Collaborative robots are lightweight and moveable. They’re easy to integrate into your existing infrastructure — no permanent or costly infrastructure changes necessary. Unlike other technologies that may take months or years to install, you can deploy them within a few short weeks and start reaping the benefits of collaborative robots immediately.

Also, collaborative robots don’t require significant space to operate or extra-wide aisles to navigate the warehouse. They can move easily throughout warehouse aisles alongside your associates and can be used on all types of warehouse floors, including rack-supported mezzanine.

2. Creating lower & flexible capital costs

One of the biggest benefits of collaborative robots is their flexibility. Working alongside human associates, collaborative robots make existing workers and new hires more efficient, helping to shore up labor gaps and facilitate the smooth running of facilities to cover short-term peaks in demand.

Rather than hiring more employees during peak periods and laying them off or keeping them on (at the detriment of bottom lines) as demand ebbs, businesses can deploy cobots as needed. For example, some collaborative robot companies allow warehouse operators to rent, buy or do both.

Some businesses choose to buy enough collaborative robots to meet their needs during periods of normal demand and rent additional units when demand increases. That means warehouses can avoid making significant capital investments in automation solutions that will only be used during peak demand periods. Instead, warehouse operators can limit capital investments to what’s needed to accommodate typical demand.

The flexibility to rent additional capacity during peak and return units when demand returns to baseline helps to ensure your fulfillment process continues to meet current and future demand. Thanks to their mobility, collaborative robots can easily be transferred to other facilities, which allows for more efficient resource utilization for multi-site warehouse operations. It also makes your warehouse more agile, reduces cost-to-serve and helps to maintain SLA compliance.

3. Increasing accuracy & reducing human error

Human error can be costly for a warehouse. Sending the wrong order can hurt customer relationships and increase return rates and refund requests. All of this can ultimately hurt your bottom line.

Designed to leverage AI and machine learning, collaborative robots can make rapid decisions and help associates more efficiently manage multiple tasks during a single trip to the warehouse floor. And because collaborative robots are guiding your associates through tasks, they also minimize the likelihood of human error.

4. Boosting productivity levels

Warehouses are large, which means associates walk long distances to find SKUs and transport orders to packing and shipping areas. The average warehouse wastes an estimated 6.9 weeks each year on unnecessary walking and other motion, which amounts to about 265 million hours of labor at a cost of $4.3 billion. Not only is excess walking costly, but it can also slow down your warehouse associates’ productivity throughout their shifts.

Collaborative robots help to speed things along by tapping into AI and machine learning to optimize picking routes in real-time, reducing unnecessary walking. By guiding associates through picking activities and other associated tasks, collaborative robots also make order fulfillment more efficient. Collaborative robots also eliminate the need for long walks between functional areas during each stage of the picking process, further reducing unnecessary travel through the warehouse for associates.

Since more is getting done in less time, it reduces physical fatigue for your associates, which can keep them working optimally. In turn, warehouses can witness a 2x to 3x increase in productivity.

5. Enhancing human labor

There’s a fear that autonomous mobile robots will take the jobs of warehouse associates. However, there’s no need to eliminate human workers. Instead, collaborative robots work alongside human associates. By making their work more efficient and minimizing unnecessary walking, which reduces fatigue, collaborative robots can help to boost employee satisfaction. With less to worry about, associates can focus on optimizing their work habits, so they become more efficient.

For example, let’s look at the typical work day of a warehouse associate. Associates have to walk through a large warehouse, picking up orders one SKU at a time. Workers place items in containers and transport them to the appropriate area, such as picking and packing areas, either manually or by pushing filled containers along on a cart. As associates fill orders, containers and carts get heavier, making them more difficult to carry or push and contributing to strain and fatigue.

Collaborative robots ease this load by guiding associates through monotonous order picking tasks and transporting orders to the right areas after picking is complete. Some cobots set the walking pace for workers. In doing so, collaborative robots free up associates to focus on more complex tasks while making order picking more desirable to employees.

6. Enhancing warehouse associate safety

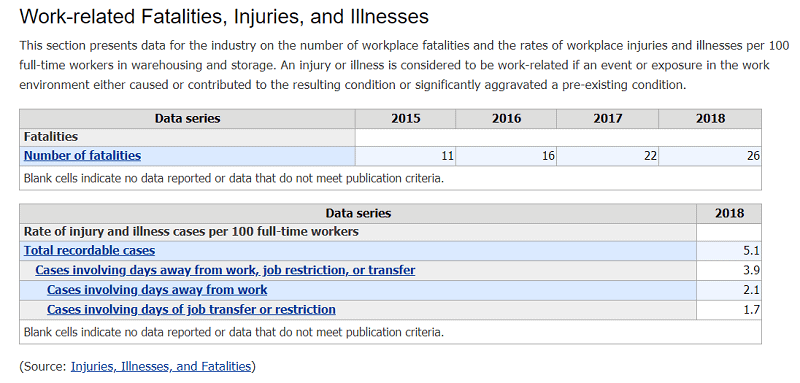

A lot can go wrong for associates in a warehouse. Boxes can fall, and associates can end up with muscle strain, back injuries or a host of other work-related injuries. According to the Bureau of Labor Statistics, there were 5.1 recordable injuries for every 100 full-time warehouse workers in 2018, with 3.9 cases out of every 100 workers involving days away from work, job restriction or transfer. There were 26 fatalities in the same year, an increase from 22 fatalities in 2017 and 16 fatalities in 2016. As a warehouse operator or manager, it’s critical to find ways to improve the safety of your workforce.

This is especially true with the negative impact on-the-job injuries can have on your company. For one, it can cost you in workers’ compensation fees. And two, it can reduce productivity levels due to missed work or unfilled positions.

Screenshot via Bureau of Labor Statistics

While some automation solutions can pose safety risks for operators or associates, collaborative robots aren’t a hazard in the workplace. In fact, they’re designed with multiple motion and force sensors that help them detect objects and people to avoid collisions. Some collaborative robots will even halt when it senses a person coming into contact in a way that’s outside its intended design. Since they optimize picking routes and automate long walks, aisles are less congested and your associates are doing less walking throughout the warehouse overall, which reduces the likelihood of accidents.

By adding collaborative robots to the warehouse, you’re automating the picking process so your workers can maintain high performance without sacrificing safety.

Advance your warehouse fulfillment process with collaborative robots

There are many ways collaborative robots can improve your warehouse functions. Collaborative robots (like pick and place robots, for example) can boost safety for your workers, increase productivity and ultimately help you save money and boost profits.

The meteoric rise of e-commerce and the unprecedented increase in the number of online shoppers (due to the COVID-19 pandemic) is driving the need for less labor-intensive ways to facilitate warehouse operations. While no technology has proved to be both as cost-effective and flexible as the human workforce, cobots have come pretty close.

Collaborative mobile robots are especially desirable because they are designed to assist (and not take over) the functions of human associates. Also, collaborative robots’ low cost and ease of deployment mean small and medium-sized warehouses can selectively deploy automation and reap its benefits at a fraction of the cost of other automation technologies.

With the pandemic disrupting supply chains across the globe, businesses must look for ways to engender efficiency and speed up order fulfillment operations as best they can. Deploying cobots in your facility can help you achieve this and much more.

With the assistance of collaborative robots, you can take your warehouse to the next level in competition and customer relationship management. Companies can now automate the repetitive and strenuous tasks in the order fulfillment process, leaving human associates free to focus on more complex and higher-value activities.

The future is here — stay competitive in today’s fast-paced logistics landscape with 6 River Systems’ collaborative robot solution, Chuck. Click here to learn more about using collaborative mobile robots for logistics and order fulfillment, or download our white paper, 7 Reasons Why Warehouse Robots Beat Traditional Automation, to learn more about why collaborative mobile robots deliver more value compared to traditional automation solutions.