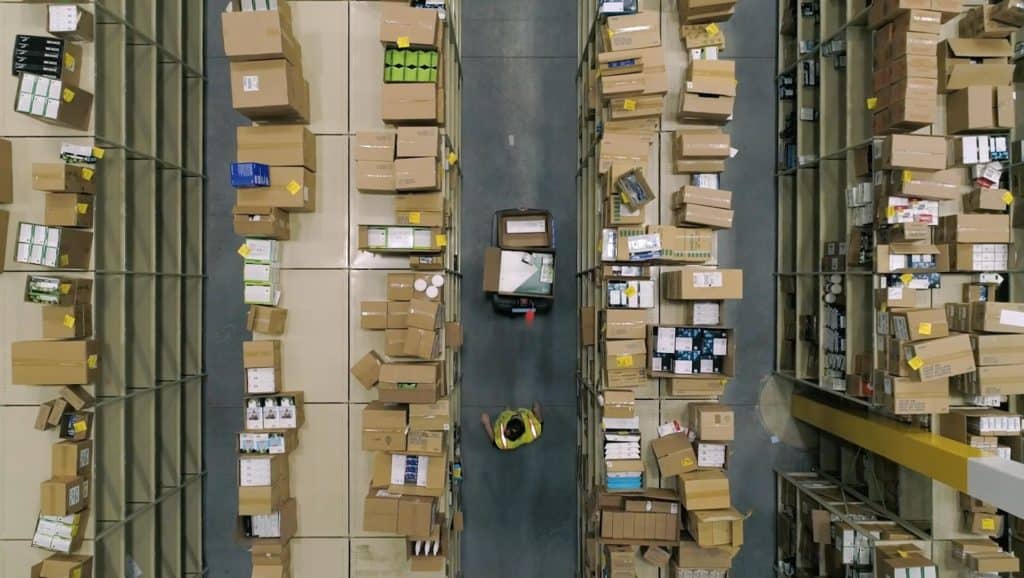

Working in a warehouse is a strenuous and time-consuming job, especially for order pickers. However, warehouse order picking is one of the most important components of the order-fulfillment process.

In fact, over half of warehouse operating costs are attributed to order picking. More importantly, fast and accurate order fulfillment leads to high rates of customer satisfaction. The order picking method used in your operation is critical for achieving business goals.

What is order picking?

Before diving into the best methods, let’s first establish what it is. Order picking is just what it sounds like: the process of retrieving products from the warehouse inventory to fulfill customer orders. It’s a labor-intensive activity that requires both speed and accuracy. The amount of time it takes to get an order together greatly influences delivery time, which is why your productivity levels are essential.

Since a worker must find the products, pick them and confirm that the correct items are selected for a customer’s order, strong organizational skills, close attention to detail and a focus on efficiency and correctness are necessary for this order picking process. Multiple techniques can be used to efficiently pick orders, including single order picking, batch order picking and wave order picking. These techniques and technology, such as handheld scanners, dramatically help streamline the order-selecting process and enhance general productivity.

Overall, order picking is labor-intensive work that is vital to the success of any order fulfillment operation. It requires meticulous attention to detail, good organizational abilities and a focus on speed and accuracy. Combining these qualities gives customers a pleasant delivery experience, making them return for more.

What does an order picker do?

In a warehouse or storage facility, solo or team-based order pickers spend more than 50% of the total order picking time traveling throughout the warehouse searching for and pulling the proper items. Pickers frequently lift and move large objects to pick items depending on the order. Aside from picking items, order pickers could also be in charge of securely and safely packaging products for shipping and ensuring that the warehouse or storage area is kept tidy and organized.

Warehouse managers could expect order pickers to operate in various settings, such as indoor and outdoor warehouses. Depending on the workload and time constraints, order pickers might also have to stand for extended periods of time. Although their work is mainly physical, order pickers must have a keen eye for detail, excellent organizational abilities, and the capacity to move fast and accurately.

Order picking is hard work that is very important to the success of the order fulfillment process. The use of robotics in the order picking process is increasing, with robot sales in North America increasing by 28% from 2020 to 2021, according to the Association for Advancing Automation. However, robots and automation don’t eliminate the need for human labor. Luckily, some methods can help to cut down on this travel time so that your company can fulfill more orders each day.

What are 6 different order picking methods?

When it comes to order picking, there are six different methods or order picking systems that can support an efficient, profitable operation.

1. Single order picking

Single order picking is the most common fulfillment method, and it is also the most time-consuming. With single order picking, the picker works on one order at a time. They’ll search the warehouse for each item one-by-one to complete the order, meaning pickers often travel the same route repeatedly throughout their shift.

Benefit:

Single order picking is ideal for smaller warehouses that handle smaller order volumes. Its simplicity makes it an appealing order picking method for new businesses.

2. Batch order picking

Also known as multi-order picking, this method allows pickers to work on multiple orders at the same time, one SKU at a time. Batch picking is best for companies that often have multiple orders with the same SKUs (items) or orders with only a few SKUs in each. It cuts down on travel time since the picker usually only needs to travel to an item location one time per picking cycle.

Benefit:

For businesses with high order volume or recurring orders, this order picking process is a quick and effective way to complete customer orders. This order picking method can manage multiple orders simultaneously while cutting down on travel time to boost production and result in cost savings for the business.

3. Pick and pass

In the pick and pass method, the warehouse is divided into zones with workers assigned to each. Warehouse pickers pick SKUs for multiple orders at a time from within their zone and the bins, totes or containers are then passed to the next zone. Pick and pass is a term often used interchangeably with zone picking, although zone picking can also be carried out without passing bins or containers from zone to zone.

Benefit:

The pick and pass method’s ability to lower the likelihood of errors by boosting picking accuracy is one of its primary advantages. The pick and pass approach improves tracking and accountability while ensuring that the correct items are picked for each order by designating zones to certain workers.

4. Zone order picking

Zone picking is often combined with other methods, most notably, the pick and pass method. With zone picking, the warehouse is divided up into zones and each picker is assigned their own zone to pull items from.

For orders that require products from multiple zones, the order container is passed on to the next zone, and that zone’s picker continues picking items for the order. This process is continued until the order is fulfilled. This method is great for high volume warehouses that often suffer from picker congestion in multiple areas.

Benefit:

The zone order picking method allows for the simultaneous picking of several orders while cutting down on travel time, potentially reducing business labor costs. This system allows for the fast handling of numerous orders while lowering the chance of errors in warehouses with picker congestion thanks to its improved tracking and accountability system.

5. Cluster order picking

The cluster picking method also allows pickers to work on multiple orders at the same time. However, instead of concentrating on similar SKUs (items) for multiple orders, pickers pick a variety of items for multiple orders. Although there are a few different ways to accomplish this (such as with vertical lift modules or carousels), the most common method is for a picker to have a cart loaded with multiple containers. The use of a picking cart or autonomous mobile robot helps pickers keep orders organized to reduce errors.

This method also cuts down on traveling, although not as much as batch picking. With cluster picking, the picker only needs to travel to an area (or zone) once for each cluster they’re working on.

Benefit:

The cluster order method empowers pickers to handle several orders while picking various items for each order, significantly reducing the time needed to complete orders and boosting overall productivity. Keeping orders sorted by using warehouse automation technologies like autonomous mobile robots helps to manage large amounts of orders while lowering the chance of errors. These benefits make it a good fit for businesses with high-volume fulfillment requirements.

6. Wave order picking

With the wave picking method, pickers also work within their assigned zones except, to cut down on time, all zones are picked from at the same time (instead of in one zone and then passed on to the next). The items are then later sorted and consolidated into their respective shipments.

While wave order picking is quicker than waiting for each zone to do their part before the order can move on to the next zone, more time and sometimes more workers are needed for the sorting and consolidation process. This method works best for companies with a higher number of picks per order.

Benefit:

The wave order picking method is a quick and effective way to complete customer orders. This method’s picking approach dramatically reduces the time it takes to complete multiple orders while boosting the overall productivity levels of pickers by allowing them to pick from all zones simultaneously.

Which order picking method is best?

You’re probably wondering which method is best for you. Unfortunately, there isn’t a single best method; the ideal order picking process can differ for each company.

The method you choose depends on how big your warehouse is, how much inventory you have, how many order pickers you have, how many orders you get each day, and how many items are in each order (picks per order). However, from this list, you should be able to choose the method that is right for your company to ensure maximum efficiency and success.

Many picking methods can be combined with automation technologies, such as autonomous mobile robots, to improve order picking accuracy and efficiency. We can also discuss the solution that’s right for you. Contact us today.