If you’re new to the warehousing process, it can feel dizzying trying to learn all the warehouse industry terminology, meanings, and workflows. We know firsthand. To better introduce our new hires to the logistics space, we created some education around common warehouse terminology and operations. We recruited our Solutions Executive Greg Walls to get in front of a whiteboard and walk us through key concepts, warehouse basics, and definitions.

Don’t have time to watch the video? Here are the cliff notes:

What is an order? And what happens when you go online to place an order?

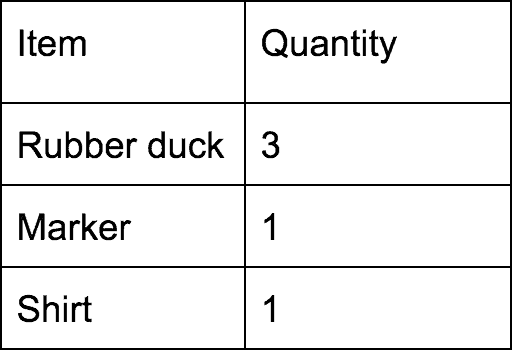

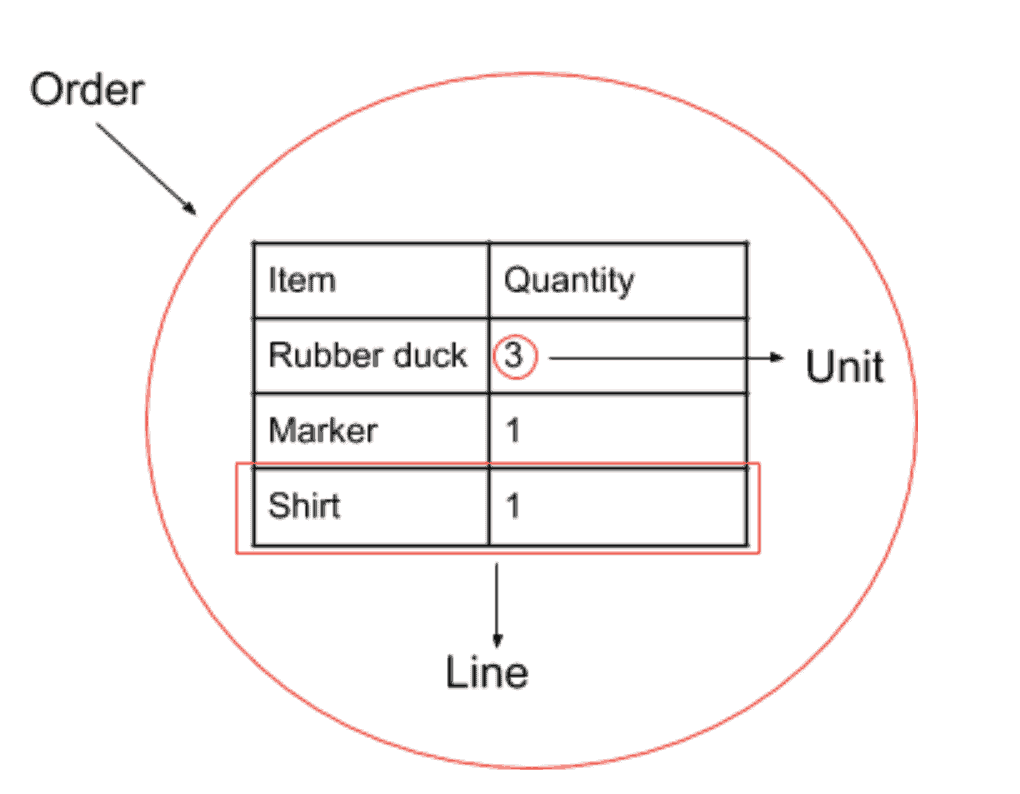

Let’s start with a fictional e-commerce order. Say you buy one marker, one shirt and three rubber ducks online. You click the shopping cart, enter your billing details and tap purchase. This is how a set of goods become an order in a warehouse’s fulfillment system.

If this seems overly simplistic — hold on. This order is actually broken down into three different components warehouses commonly refer to: order, lines and units.

Order: The “shopping basket” full of items you’ve just purchased.

Lines: The different products within your order, recognized by warehouses as each individual Stock Keeping Unit (SKU) or Universal Product Code (UPC) number.

Units: The quantity of each line.

So, your e-commerce order above can be broken down into:

- 1 order

- 3 lines

- 5 units

What does the full process, from manufacturing to the product arriving at my doorstep, look like?

You’ve placed an order, and someone in a warehouse will eventually pick, pack and ship it to your doorstep. But how does the product get to the warehouse in the first place?

Assuming it’s already been manufactured, products are shipped to a fulfillment or distribution center. Products arrive to the warehouse in pallets, which are broken down into cases, and moved into an active pick area, ready to be picked into orders.

How does my order get picked?

There are a few different ways to pick orders in warehouse, but in this video we cover two methods:

Discrete picking: When pickers take each individual order and pick it into a box, which is then directly shipped to the consumer. So, one person picks your rubber ducks, marker and shirt into a container that will eventually end up on your doorstep.

Batch picking: Batch picking is when you group a bunch of orders into one tote. One person picks 100 people’s rubber ducks in one shot, and then someone else sorts that batch into your individual order.

This is where the 6 River Systems solution helps, by making picking faster and better through our collaborative mobile robot Chuck. 6 River Systems and Chuck support both types of picking, even at the same time.

What is UPH?

UPH stands for units per hour. It means just that — how many units are picked in an hour. While warehouses may use other metrics, like Lines Per Hour (LPH), most warehouses use UPH as their base throughput metric to measure efficiency.

For more resources related to the warehousing process and warehouse terms, check out:

- The ultimate guide to warehouse order picking

- Types of automated storage and retrieval systems

- 50 expert warehouse management best practices