Many fulfillment operations experience a peak season in the warehouse: a period of time in which order volume increases significantly above the average. The most substantial retail peak occurs during the holiday season, between Black Friday and Christmas. During these four weeks, volume increases anywhere from 2x to 10x, generating a disproportionate amount of volume and revenue.

For most operations, this short-lived volume increase makes it both inefficient and costly to make any major infrastructure transformations within the warehouse. Historically, warehouse operators have relied primarily on seasonal labor to increase throughput to meet peak demand. However, due to record low unemployment rates in recent years, this approach is no longer feasible.

In September 2018, unemployment rates in the US dropped to 3.7%. This marked the lowest rate in the US since 1969, and it has remained in the 3.6% to 4% range through October of 2019. This labor shortage caused 20% of warehouse jobs to go unfulfilled in 2018, and similar outcomes are forecast for this peak season. Even after operators increased wages in an effort to attract employees, the available supply remained so limited that this gap could not be bridged.

To further exacerbate this dilemma, customer expectations around delivery time have drastically increased. With Amazon as the number one online retailer offering free one-day shipping–and, most recently, two-hour shipping–consumers expect their packages to arrive immediately and free of charge.

This shift in expectations has caused the bar for fulfillment to be higher than ever before. If retail and ecommerce warehouses are unable to keep up with Amazon’s standards, especially during peak, they risk losing market share to those who do.

The case for collaborative robots:

Scalability, quick implementation, labor shortage

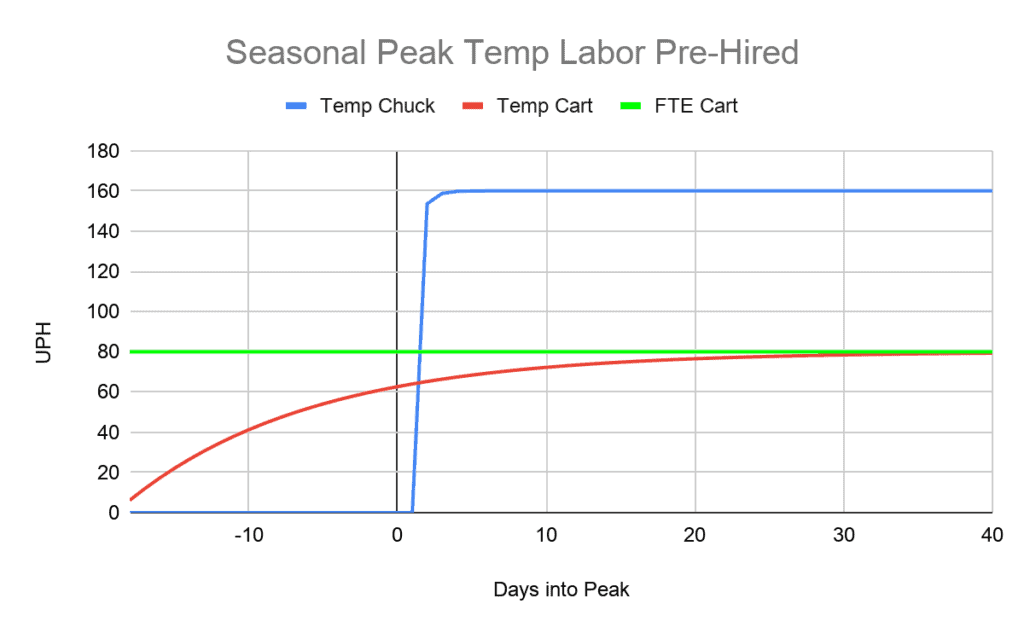

Collaborative robots, or “cobots,” are the new way warehouses fulfill. Their flexible and adaptive capacity allow them to increase both productivity and order selection accuracy in warehouse operations. These benefits are especially critical during volume peaks, as the ongoing labor shortage prevents operations from being able to rely on seasonal labor to bridge the gap.

Therefore, it should come as no surprise that cobots are on the rise. ABI Research projects the current number of robotic warehouses to grow by more than 12x by 2025, at which point there will be 4 million commercial robots in over 50,000 warehouses.

Below are some of the key flexibility factors throughout the entire life cycle that make cobots so compelling:

| Stage | Option | Impact |

| Purchasing | Rent, buy, or hybrid options are available. Some companies purchase for average volume, and rent additional robots to scale for peak. | Financial flexibility. Systems can be acquired through capital or operating budgets. |

| Implementation | Utilize existing infrastructure, including WMS, racking, etc. | Delivers a full ROI in less time than a traditional automation or goods-to-person system can be implemented. |

| Operations | Add or remove capacity; gain the capability to quickly change picking methods to meet future demand. | Improved operations performance, agility, capacity, SLA compliance, and reduced cost-to-serve. |

| Service delivery and support | System enhancements delivered via the cloud. | Receive system upgrades and additional functionality without any disruption to your operation. |

How to achieve peak productivity:

Consider experience, solution breadth, fast ROI

While there are several different collaborative robotics systems to choose from, 6 River Systems’ (6RS) solution is uniquely differentiated from its competitors.

- Team: The founders are former Kiva executives, and possess unmatched experience and success in designing and implementing successful warehouse robotics systems. The team has installed more collaborative robotics systems than any other company.

- Product Line: With fully automated picking, sorting, and packout products launched in 2019, 6RS has extended its capabilities to an end-to-end fulfillment solution. The system, based on a patented worker directed approach, integrates with a wide variety of material handling and software systems.

- Ongoing Value: Chucks gain core product functionality in addition to new features every year. Chuck was initially released as a cobot for discrete order picking. Just 2½ years later, the same Chuck also can batch pick, replenish, be used in automated picking, and charge automatically when its battery is low. The capabilities will expand even further by next peak season.

- Analytics: Embedded dashboards provide operational insights on associate performance and hours worked by task type. Operators leverage this data to identify potential problem areas and for labor planning.

- Customer Success Focus: After implementation, 6RS assigns a multi-disciplinary, dedicated team with a single point of contact to ensure success. 6RS has committed to raising the average performance rate of its customer sites over the course of 2020.

- Return on Investment: 6RS increases productivity by 2-3x and is installed in weeks, making the return on investment extremely compelling.

6 River Systems customer success stories

|

“We think we’ve found a really great partner in 6 River and a really great technology on Chuck. We look forward to building upon that and taking off from here as we continue to improve our operations.” – Bob Abbondanza, Senior Director Supply Chain Engineering and Network Design |

|

“In peak season, we will have a greater capacity and be able to pick more with less labor by using 6 River Systems.” – Ryan Robertson, Director of Operations, Retail Logistics |

|

“We hit a return on investment with 6 River Systems in about 4 months. We wanted to streamline the process and remove as many steps as possible. With 6 River Systems, pickers stay in aisle the entire time and the amount of units they’re processing per hour has tripled.” – Ryan Cox, Industrial Engineer |

For more information, review success stories from several 6RS customers, including ACT Fulfillment Center, NFI, Healing Hands, and Office Depot. We can also discuss the solution that’s right for you. Contact us today.

About the Author

Callie Moriarty is one of 6 River Systems’ first Customer Success Managers. She is responsible for the optimization, success, and overall customer satisfaction at ten live 6RS customer sites. After being a part of 6RS’ holiday peak season in 2018, she wanted to share the overwhelming value of collaborative robotics with her current and future customers.